EDM Wire

Stainless Steel Products is an authorized exclusive distributor of high-quality SENOR EDM wire.

EDM Wire, a crucial component in Electrical Discharge Machining (EDM), serves as the electrode that enables precision machining of intricate shapes and profiles in hard materials.

Features and Benefits

1. Very good straightness, excellent in auto threading applications, especially in Jananese and German cutting machines.

2. Excellent Surface Finish

3. Good Roundness

4. Inline Japanese Continuous Annealing Technology ensures a stable and uniform tensile strength preventing wire breakage.

5. Manufactured with a high precision and wire diameter tolerance of +0.000 / -0.002mm with smooth surface free from flaws or irregularities.

6. Higher Cutting efficiency

EDM Wire Specifications

| Sr. N | Wire Diameter | Diameter Tolerance | Wire Grade | Tensile Strength | Elongation | Wire Spool Types |

| mm | mm | Mpa | % | |||

| 1 | 0.10 | +0 / -0.002 | Hard | >980 | <= 2 | DIN-125, P5 |

| 2 | 0.15 | +0 / -0.002 | Soft | 450 - 550 | >25 | |

| +0 / -0.002 | Semi-Hard | 550 - 750 | >10 | DIN-125, P5 | ||

| +0 / -0.002 | Hard | >980 | <=2 | |||

| 3 | 0.20 | +0 / -0.002 | Soft | 450 - 550 | >25 | DIN -125, DIN-160, DIN-200 |

| +0 / -0.002 | Semi-Hard | 550 - 750 | >10 | DIN-250, P-5, P-10, P-15 | ||

| +0 / -0.002 | Hard | >980 | <=2 | |||

| 4 | 0.25 | +0 / -0.002 | Soft | 450 - 550 | >25 | DIN -125, DIN-160, DIN-200 |

| +0 / -0.002 | Semi-Hard | 550 - 750 | >10 | DIN-250, P-5, P-10, P-15 | ||

| +0 / -0.002 | Hard | >980 | <=2 | |||

| 5 | 0.30 | +0 / -0.002 | Soft | 450 - 550 | >25 | DIN -125, DIN-160, DIN-200 |

| +0 / -0.002 | Semi-Hard | 550 - 750 | >10 | DIN-250, P-5, P-10, P-15 | ||

| +0 / -0.002 | Hard | >980 | <=2 |

*This is for information purposes only. Actual numbers may vary.

Steps in EDM Wire Manufacturing Process

1. Copper cathode, Special high-grade Zinc and Master alloys.

2. Induction Melting

3. Alloy Forming verified through Spectrum Analysis.

4. Dispatch

5. Packing under controlled environment.

6. Total Quality Assurance

7. Inline Annealing, Spooling, and Change over

8. Consecutive Automatic Operations in Drawing Process.

Electrolytic Zinc Plated Brass EDM Wires

Zinc-coated wires manufactured on European Technology consists of brass wire electroplated with high purity zinc. the high plating accuracy realizes faster cutting speed and provides a better surface finish on the work piece.

Features

- High purity uniform zinc layer

- Impurities are kept to the minimum, thus preventing deterioration of performance

- The discharge is stable and free of irregularities

- High cutting rates

- Reduced tendency of wire breakage and copper deposit

- 6. Excellent value for money

High quality diffused EDM Wires for High Speed EDM Machines. This diffused EDM wires are coated and diffused to give better cutting speed, up to 25% then plain wires.

Alloy Codes

A1 = CuZn40 A2 = CuZn37 A3 = CuZn35

Process Type and Recommended Wire Grade

| No. | Process Type | Cutting | Wire Type | ||

| Soft | Semi-Hard | Hard | |||

| 1 | Straight Cutting | 1 Pass Cutting | Not Recommended | Good | Excellent |

| Straight Cutting | 2 Pass Cutting ( Rough + Finish) | Not Recommended | Not Recommended | Excellent | |

| Straight Cutting | 3 Pass Cutting ( Rough + Finish + Refinish) | Not Recommended | Not Recommended | Excellent | |

| 2 | Relief Cutting | 1 Pass Cutting Relief under 10° | Not Recommended | Good | Excellent |

| Relief Cutting | 1 Pass Cutting Relief under 10° to 20° | Good | Excellent | Not Recommended | |

| Relief Cutting | 1 Pass Cutting Relief over 20° | Excellent | Good | Not Recommended |

Notes:

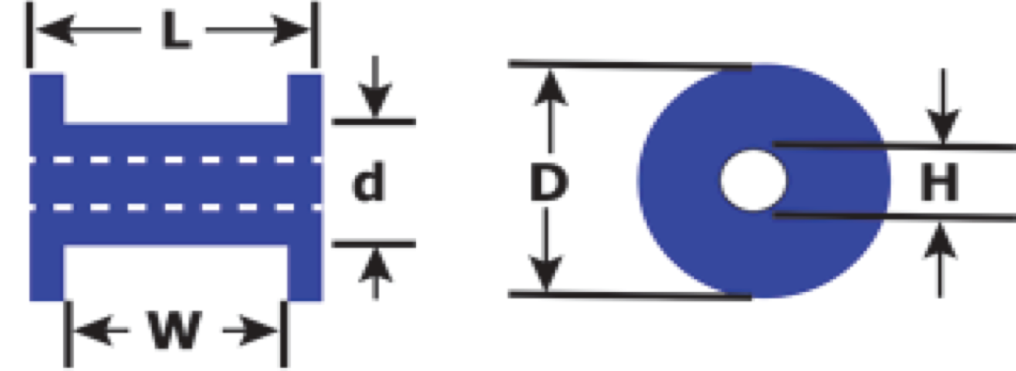

1. These spool dimensions are proved as general information, and are typical dimensions only. Spool manufacturers are not completely consistent with these dimensions.

2. EDM wires are wound on spools, wrapped by brown paper followed by plastic shrink packing and packed in shock-proof and weatherproof corrugated box.

| Spool Type | D | d | L | W | H | Net Weight |

| (mm) | (mm) | (mm) | (mm) | (mm) | Spool (Kg) | |

| DIN-125 (K-125) | 125 | 80 | 125 | 100 | 16 | 3.5 |

| DIN-160 (K-160) | 160 | 100 | 160 | 130 | 22 | 7 |

| DIN-200 | 200 | 125 | 200 | 160 | 22 | 14 |

| DIN-250 | 250 | 160 | 200 | 160 | 22 | 20 |

| P-5 | 160 | 90 | 115 | 90 | 20 | 5 |

| P-10 | 200 | 90 | 134 | 110 | 30 | 10 |

| P-15 | 250 | 110 | 140 | 131 | 32 | 15 |

Materials

Ferrous or non-ferrous, we work with most alloys available on the market today. Below is a list by major alloy family class:

Industries We Serve

SSP works with all major industries on various product applications. Take advantage of our breadth of knowledge on a wide variety of specifications and requirements!